Key Modular Robot Design Concepts You Need to Know

Imagine a world where robots can reshape themselves to tackle any task, adapt to changing environments, and work seamlessly alongside humans. This is not just a vision for the distant future; it’s becoming a reality with modular robot design concepts. These innovative systems consist of interchangeable units that collaborate, reconfigure, and evolve according to their surroundings or mission requirements.

In today’s fast-paced technological landscape, understanding these concepts is essential for anyone interested in robotics. Whether you’re an industry professional or simply curious about how robots are revolutionizing various fields, grasping the fundamentals of modular robot design will open your eyes to endless possibilities. Let’s delve into the core principles that define this exciting area of robotics!

Benefits of modular robot design

Modular robot design offers numerous advantages that make it a game-changer in robotics. One of the primary benefits is versatility. These robots can be easily reconfigured to perform different tasks, reducing the need for multiple machines.

Cost-effectiveness also plays a significant role. Instead of investing in several specialized robots, businesses can utilize modular designs to adapt and reuse existing components for various applications.

Maintenance becomes more manageable with these systems. When a part fails, you only need to replace that specific module rather than the entire unit, leading to reduced downtime.

In addition, scalability is inherent in modular designs. Companies can start small and expand their robotic capabilities as needs grow without overhauling their infrastructure entirely.

Enhanced collaboration between modules fosters innovation. Different configurations allow teams to experiment freely and discover new functionalities or improvements tailored to unique challenges.

Key concepts in modular robot design:

Modular robot design is built on several key concepts that enhance functionality and efficiency.

First, modularity and reconfigurability allow robots to adapt to different tasks by rearranging their components. This flexibility makes them suitable for various environments.

Scalability and adaptability are also crucial. Robots can grow in size or complexity based on project requirements, making them versatile across multiple applications.

Interchangeable components further improve usability. By swapping out parts, users can customize robots easily without needing specialized tools or extensive training.

Self-reconfiguration enables robots to change their structure autonomously in response to situational demands. Coupled with self-assembly capabilities, these systems can form new shapes and functions independently.

These elements together create a robust framework for innovative robotic solutions tailored to unique challenges.

A. Modularity and reconfigurability

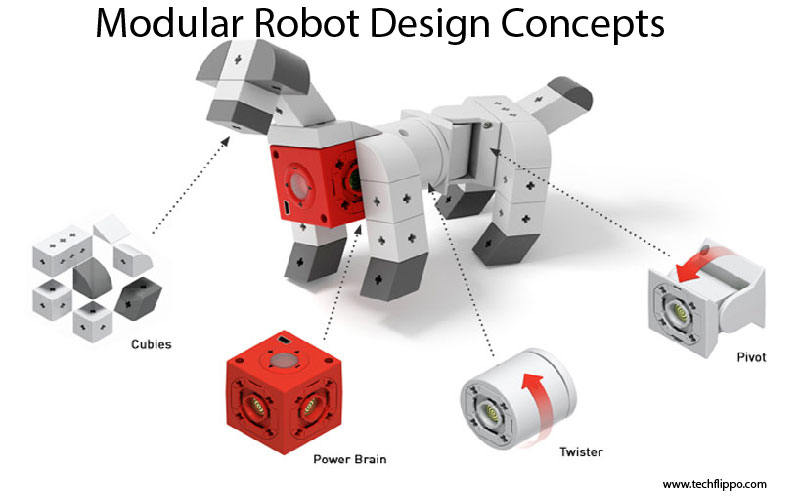

Modularity is the cornerstone of modern robotic design. It allows robots to be constructed from interchangeable units, or modules, each serving a specific function. This setup fosters creativity in engineering.

Reconfigurability enhances this concept further. Robots can be adapted for various tasks simply by rearranging or replacing these modules. Imagine a robot that starts as an assembly unit and transforms into a surveillance device just by switching components.

This flexibility not only saves time but also cuts costs significantly. Engineers can optimize robotic systems for different environments without starting from scratch every time.

Moreover, modularity encourages experimentation and innovation in robotics. Developers are free to test new configurations quickly, leading to rapid advancements in functionality and efficiency within the field.

B. Scalability and adaptability

Scalability and adaptability are vital aspects of modular robot design concepts. These features enable robots to grow in size or functionality based on specific tasks or environments.

A scalable modular robot can easily integrate additional modules, enhancing its capabilities as needs evolve. This makes it suitable for various applications, from simple assembly tasks to complex operations in unpredictable scenarios.

Adaptability goes hand-in-hand with scalability. Modular robots can quickly adjust their configurations according to real-time demands. Whether navigating tight spaces or working alongside humans, they change their structure seamlessly.

This flexibility is crucial across industries such as manufacturing and healthcare, where workflows often shift unexpectedly. The ability to adapt not only maximizes efficiency but also ensures that the technology remains relevant amid changing market needs.

C. Interchangeable components

Interchangeable components are a game-changer in modular robot design. This feature allows users to swap out parts easily, depending on specific tasks or requirements.

Imagine a robotic system that can shift from assembly line work to exploration missions simply by changing its limbs or sensors. This versatility not only enhances functionality but also reduces downtime.

The ability to replace damaged or outdated parts without overhauling the entire robot makes maintenance more straightforward and cost-effective. Organizations can keep their robots up-to-date with the latest technology, ensuring peak performance across various applications.

Moreover, interchangeable components foster innovation. Designers can experiment with new attachments, driving creativity and advancements within robotics without starting from scratch each time. It’s an exciting aspect that opens doors to endless possibilities in robotic applications.

D. Self-reconfiguration and self-assembly

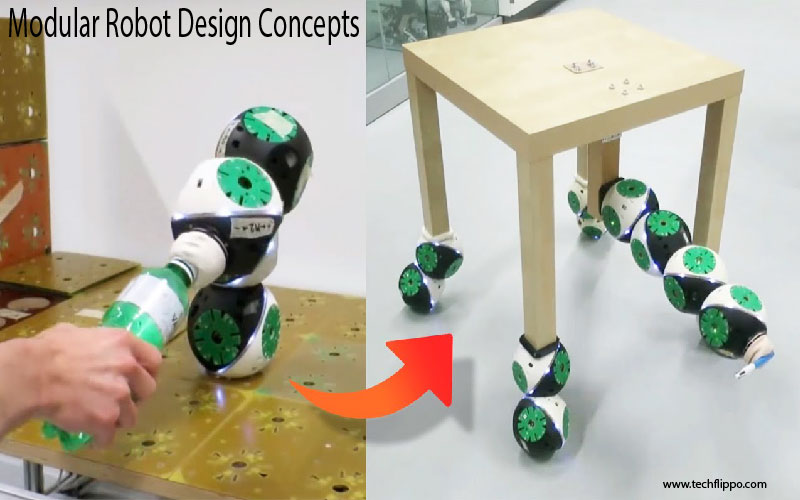

Self-reconfiguration and self-assembly are groundbreaking concepts in modular robot design. They enable robots to change their structure autonomously, adapting to different tasks or environments.

Imagine a swarm of small modules that can transform into various shapes based on the job at hand. This capability enhances flexibility and efficiency. For instance, a team of robots could reconfigure themselves from a single long line for transporting materials into a compact shape for navigating tight spaces.

The process usually involves sophisticated algorithms that dictate how each module should move and connect with others. Sensors play an essential role, providing real-time feedback about surrounding conditions.

This adaptability not only saves time but also allows for innovative solutions in unpredictable scenarios. Whether it’s exploring disaster zones or assembling complex structures, self-reconfiguring robots hold immense potential across many fields.

Applications of modular robot design in various industries

Modular robot design finds its way into a multitude of industries, showcasing remarkable versatility. In manufacturing, these robots streamline assembly lines and allow for rapid reconfiguration to adapt to different products.

Healthcare also benefits significantly. Modular robots assist in surgeries, providing precision and flexibility that traditional systems cannot match. They can be easily customized for specific procedures or adapted as technology evolves.

In agriculture, modular robots facilitate tasks like planting and harvesting. Their ability to operate collaboratively enhances productivity while minimizing labor costs.

The logistics sector leverages modular designs for warehouse automation. Robots can shift from sorting packages to transporting goods seamlessly based on immediate needs.

Even in disaster response scenarios, modular robots play a crucial role by navigating unpredictable environments. They can assemble or disassemble quickly depending on the situation at hand. This adaptability makes them invaluable across diverse fields.

Challenges and limitations of modular robot design

Modular robot design certainly has its appeal, but it’s not without challenges. One significant hurdle is the complexity of coordination among modules. Each unit must communicate effectively to perform tasks seamlessly.

Another issue lies in the materials used for construction. While modular robots seek versatility, finding lightweight yet durable components can be tough. This often leads to compromises that affect performance and longevity.

Cost also poses a barrier. Developing advanced modular systems requires substantial investment in research and technology, making them less accessible for smaller companies or startups.

Additionally, programming these robots can be intricate. Custom software solutions are needed to manage configurations and behaviors, which demands specialized expertise that isn’t always readily available.

Scalability remains a concern as increasing the number of modules doesn’t always translate into efficiency gains; sometimes it results in diminishing returns due to added complexity in management and operation.

Future developments in the field

The future of modular robot design is brimming with potential. Researchers are exploring advanced materials that can enhance flexibility and durability. This could lead to robots capable of operating in diverse environments, from outer space to deep-sea exploration.

Artificial intelligence plays a crucial role in the evolution of these systems. As AI algorithms become more sophisticated, modular robots will gain improved decision-making capabilities. They may even be able to adapt their configurations on-the-fly based on real-time data.

Additionally, collaboration among various robotic units could revolutionize industries like manufacturing and healthcare. Imagine a swarm of tiny robots working together seamlessly to complete complex tasks.

Sustainability is also becoming a focal point for developers. Future designs may prioritize eco-friendly materials and energy-efficient operations, aligning technological progress with environmental responsibility. The horizon looks promising for those invested in this exciting field!

Conclusion

Modular robot design concepts are transforming the landscape of robotics. They offer flexibility, efficiency, and adaptability that traditional robots simply cannot match. The ability to reconfigure systems based on specific tasks is a game-changer across countless industries.

As we continue to explore these innovative designs, it’s clear they hold immense potential for future applications. From manufacturing to healthcare and beyond, modular robots could revolutionize how we approach complex problems.

Challenges still exist in this field. Addressing scalability issues and ensuring seamless interoperability among components will be crucial as developments progress. However, with ongoing research and advancements in technology, the horizon looks promising for modular robotics.

The journey of modular robot design is just beginning. Embracing these key concepts can unlock new possibilities that push the boundaries of what robots can achieve in our daily lives.